Manufacturing is always under tremendous pressure to decrease costs while continuing to deliver high-quality products and services. Prof Klaus Schwab of the world economic forum believes “The Fourth Industrial Revolution” is happening and that AI is set to transform the present world. Research shows that 58 percent of manufacturers are actively interested in using AI, whereas only 12 percent are implementing it.

Some large manufacturers have adopted AI-driven methods as short cut solutions, but smaller manufacturing units lack real-data to follow suit. Gathering data is currently inexpensive, and we expect at least a 30 percent implementation in the near future.AI-powered analytics on data in manufacturing industry promises to offer a massive improvement in productivity, efficiency, quality, the safety of employees and cuts in unplanned downtime, etc. Here are some ways you could transform your industry into a Smart Factory:

1. Predictive Maintenance or Smart Maintenance

Predictive maintenance directly monitors the condition and performance of the equipment to reduce the likelihood of failures. It diminishes the frequency of the maintenance tasks by reducing unplanned breakdowns and eliminating unnecessary preventive maintenance.

Studies show that unplanned downtime costs manufacturers an estimated $50 billion annually and that asset failure is the cause of 42 percent of this downtime. AI algorithms in machine learning and artificial neural networks (Deep Learning) predict the asset malfunction thereby reducing costly unplanned downtime as well as improving the Remaining Useful Life (RUL) of production machines and equipment. Hence, predictive maintenance is a necessary strategy for manufacturers to cut costs. Smart factories of a leading automotive manufacturer use Azure Machine Learning to detect and predict defects in their machinery before issues arise.

Flow Diagram for Predictive Maintenance

2. Automate Quality Checks

Factories creating products like microchips and circuit boards employ Machine vision, which combines AI with high-resolution cameras. Minute defects are picked far more accurately than the human eye, instantly flagged, and a response is coordinated by using cloud-based data processing framework.

3. Faster, more reliable design

The AI algorithms in generative design are being used to create thousands of component designs in seconds. The input to these AI algorithms are material types, available production methods, budget limitations, and time constraints. The algorithm explores every possible configuration before coming up with the ideal solution. The suite of solutions can be tested using machine learning offering additional insights as to which design works best. The process can be repeated until it finds an optimal design solution.

4. Supply Chain Communication

AI algorithms can also be used to optimize manufacturing supply chains, helping companies anticipate market changes. This gives management a colossal advantage, moving from a conservative mindset to a strategic one. This is essential as the making manufacturing industry adapts to the ever-changing market.

AI algorithms formulate estimations of market demands by looking for patterns linking location, socioeconomic and macroeconomic factors, weather patterns, political status, consumer behavior and more.

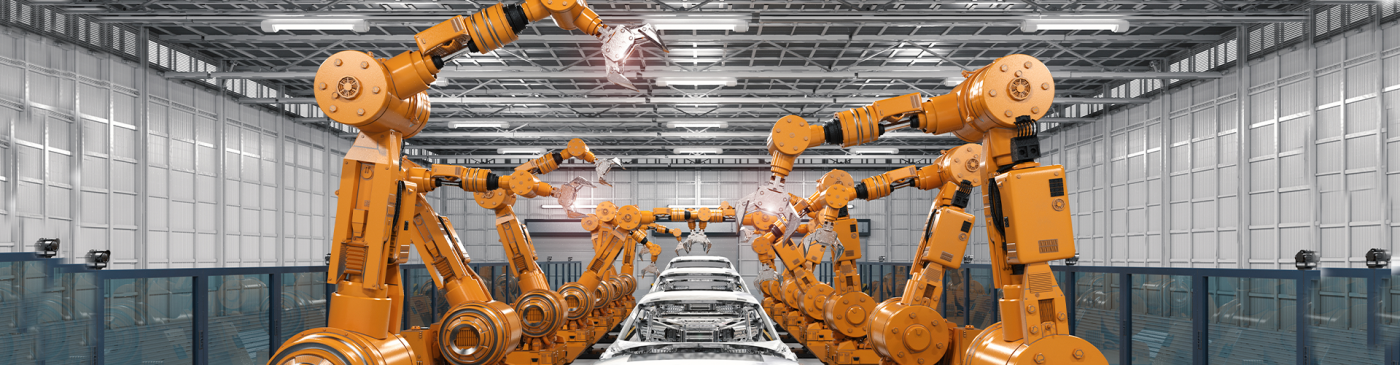

5. Human-Robot collaboration

Currently, there are more than 1.3 million industrial robots at work in factories all over the world. As more jobs are assigned to robots, workers can be trained for more advanced positions in design, maintenance, and programming. Also, assigning risky work to improves safety at the manufacturing sites. Deep Learning is already enhancing this development, enabling robots to handle more cognitive tasks and make autonomous decisions based on real-time environmental/operational data, further optimizing the process.

6. Reducing waste

Using AI, the wastage was decreased by 15 percent, saving billions of dollars in the process.

Thus AI in manufacturing is reaching a full range of adoption. McKinsey predicts that smart factories will contribute $37 trillion in new value by 2025.

Understanding the domain and the associated AI applications will significantly increase utility and improve revenue. Engage with SAAL to understand how we can partner with domain experts in the Manufacturing Industry to extract insights from data and utilize them to build efficient AI-based decision support system.